GK type horizontal scraper discharges

Classification:

Hot line:+86-0830-3585666

Sales:+86-18121975532

General:+8615328339822

Product Description

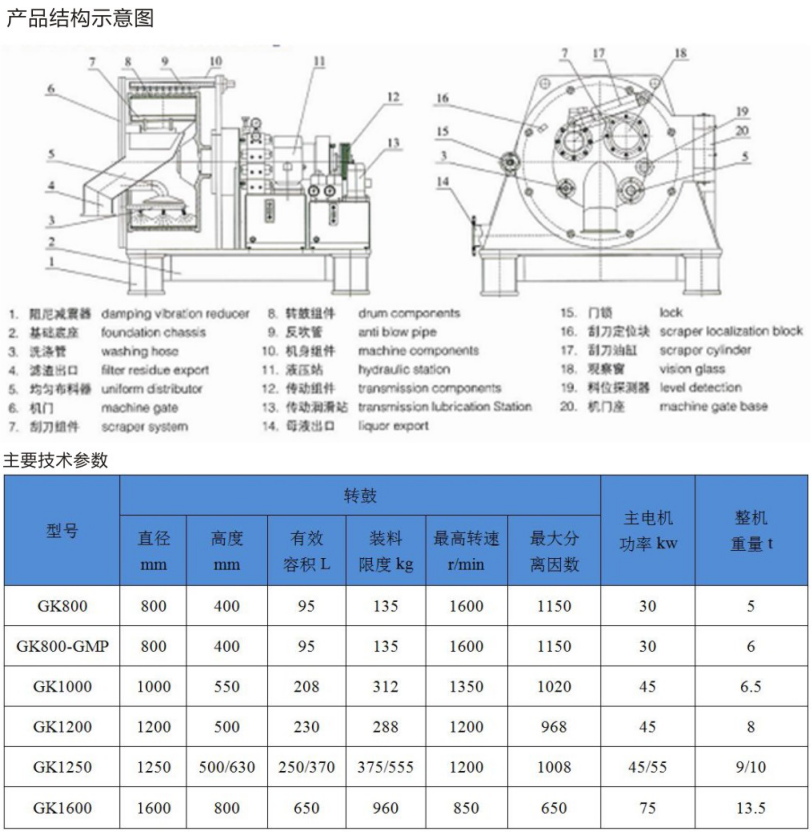

Product structure features

After the motor drives the drum to run at full speed, the feed valve is automatically opened, and the suspension enters the drum along the feed pipe, in which the liquid phase is centrifugally thrown out through the filter screen and the filter hole of the drum wall, and flows out from the tangential liquid discharge port on the casing, and the solid phase is intercepted in the drum. After reaching the set time, the feeding stops, after a given time of separation and dehydration, the washing valve acts, the washing liquid enters the drum by the washing tube, and the filter cake is washed, and the separation is continued after the washing is over, so that the filter cake reaches the required dryness, and then the material is discharged, and the scraper holder rotates to make the scraper cut into the filter cake layer, scrape the filter cake and exclude it from the hopper.

Product Use

:The GK centrifuge is a kind of filtration equipment with continuous operation, scraper discharge, and intermittent operation. It is suitable for separating suspensions of medium or fine particles (0.01mm-5mm), and can also separate suspensions of short fibers (fiber length less than 4mm); The concentration of the suspension ranges from 10% to 60%. This series of centrifuges adopts a combination of hydraulic and electrical control, which can achieve a high degree of automation. Feeding, deliquidation, washing, unloading and other processes can be operated manually, and PLC can be used to achieve fully automatic control. Due to the strong adaptability of the horizontal scraper discharge centrifuge to the material, it is widely used in chemical, light industry, food, pharmaceutical and other industries. Such as ammonium sulfate, sodium sulfate, sodium chloride, anthracene, shed acid, starch, pesticides, synthetic resins, sodium chloride, potassium chloride, sodium bicarbonate, etc.

Key words:

RedRock Machinery, Centrifuge

Previous: None

Next: GKH Horizontal (Siphon)

Related Products

Provide you with centrifuge solutions

SAF Coolest v1.3.1.2 设置面板 AOYSD-ZSXM-GASVE-AZF

无数据提示

Sorry, the current column is being updated, please look forward to it!

You can view other columns or returnHome Page