Product display

Integrity first, win-win cooperation, do our best to create the greatest value for customers.

LWL horizontal filter sedimentation centrifuge

LW (LWS) screw pusher centrifuge

LLW type horizontal screw discharge

LWZ sedimentation concentration type helix

GK type horizontal scraper discharges

-

Municipal sewage

RedRock Machinery

-

Industrial products and wastewater

RedRock Machinery

-

Metallurgical wastewater

RedRock Machinery

-

Construction mud

RedRock Machinery

-

Oil and Gas

RedRock Machinery

-

Food and Medicine

RedRock Machinery

-

Aquaculture wastewater

RedRock Machinery

-

Other industries

RedRock Machinery

ABOUT US

Luzhou Jiangyang RedRock Machinery Co., Ltd.

The company is a national high-tech enterprise integrating R & D, production, sales and after-sales service. The company was established in 2009 and has successively joined the Separation Machinery Branch of China General Machinery Industry Association and China Inorganic Salt Industry Association. The company passed the ISO9001-2008 of China Quality Certification Center in 2013 and successfully changed its ISO9001-2015 in 2019.

The company is located in Luzhou National High-tech Zone, close to Luzhou Port, about 10 kilometers away from Yunlong Airport, with a very convenient transportation environment.

One-stop centrifuge professional manufacturer

Hard work, steady work, responsibility

-

2009

年公司成立

-

180

+驾驶员180余人

-

80

+装卸人员80余人

-

325

+自有及挂靠车辆

-

99

%+客户满意度99%+

Honor

Integrity first, win-win cooperation, do our best to create the greatest value for customers.

COOPERATION CUSTOMERS

In strict accordance with the centrifuge manufacturing standards, the company digests and absorbs advanced technology at home and abroad in product design, compiles detailed and feasible production technology, strictly controls the product quality process, and establishes a perfect sales and after-sales service system. At present, our company has realized the production and sales of plate type, siphon scraper, horizontal screw, bipolar and other series centrifuges, The company's products are widely used in medicine, chemical industry, food, environmental protection and other fields, with first-class product quality, superb technical support and timely and thoughtful service, won the majority of users.

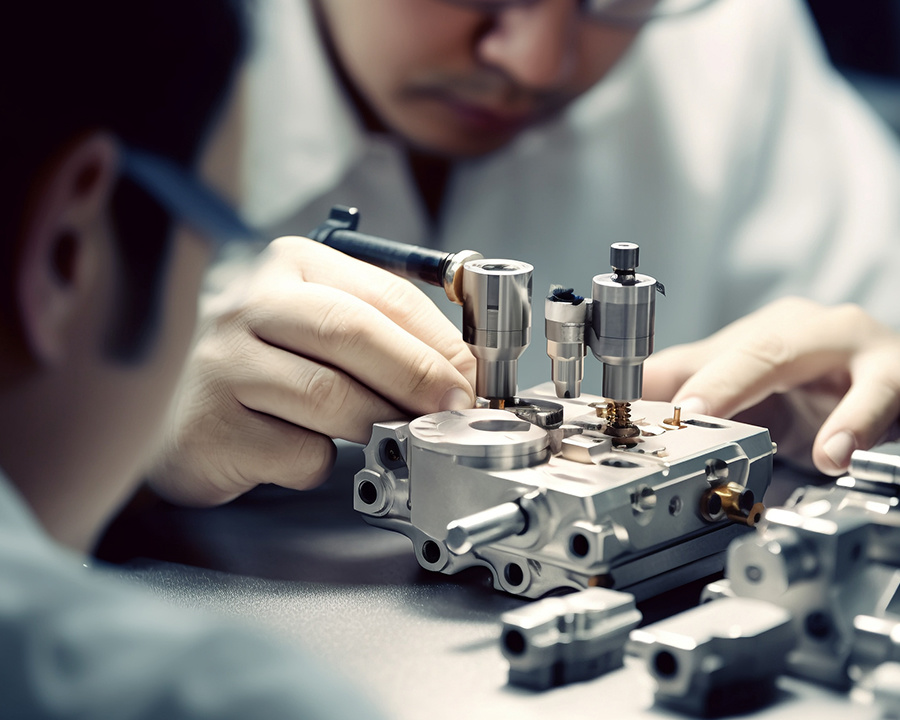

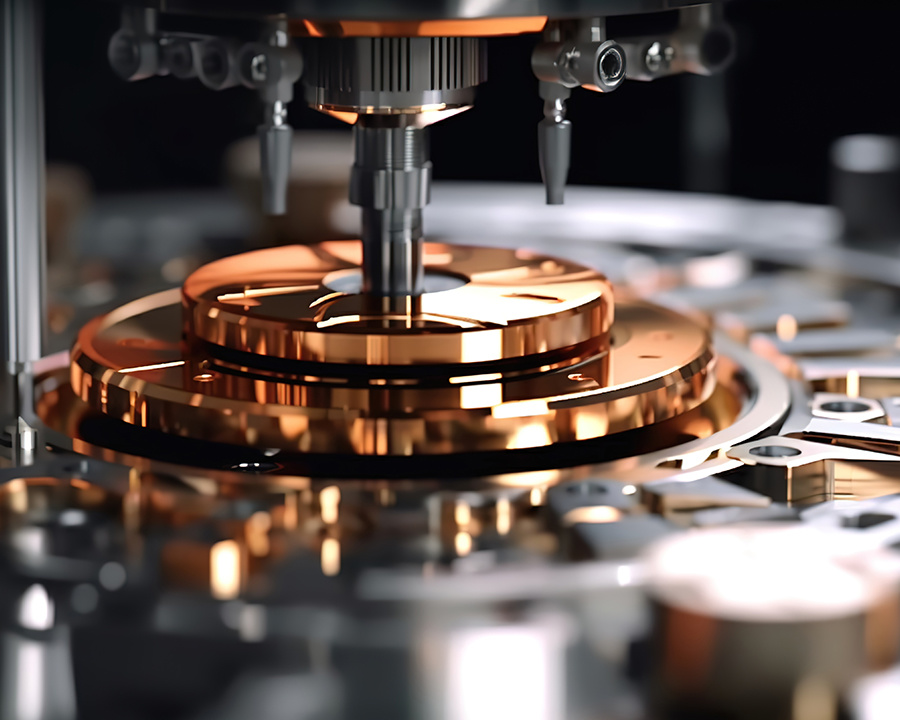

Large-scale production workshop

Large vertical lathes

Large horizontal lathes

News Center

SAF Coolest v1.3.1.2 设置面板 AOYSD-ZSXM-GASVE-AZF

无数据提示

Sorry, the current column is being updated, please look forward to it!

You can view other columns or returnHome Page